Greenzyme

Greenzyme facilitates a waste-reducing lifestyle by empowering households to transform food waste into useful eco-enzyme products. It streamlines the fermentation process by automating gas release and tracking pH levels to alert spoilage. The system is supported by a smartphone app that provides recipes and information on dates, ingredients, and fermentation status.

Mar - Apr 2024

Designer

Engineer

What is Eco-Enzyme?

Eco-enzyme is a biodegradable liquid produced from fermenting kitchen waste, used as a natural cleaner, pesticide, and fertilizer, harnessing waste to benefit the environment.

Previous User Flow

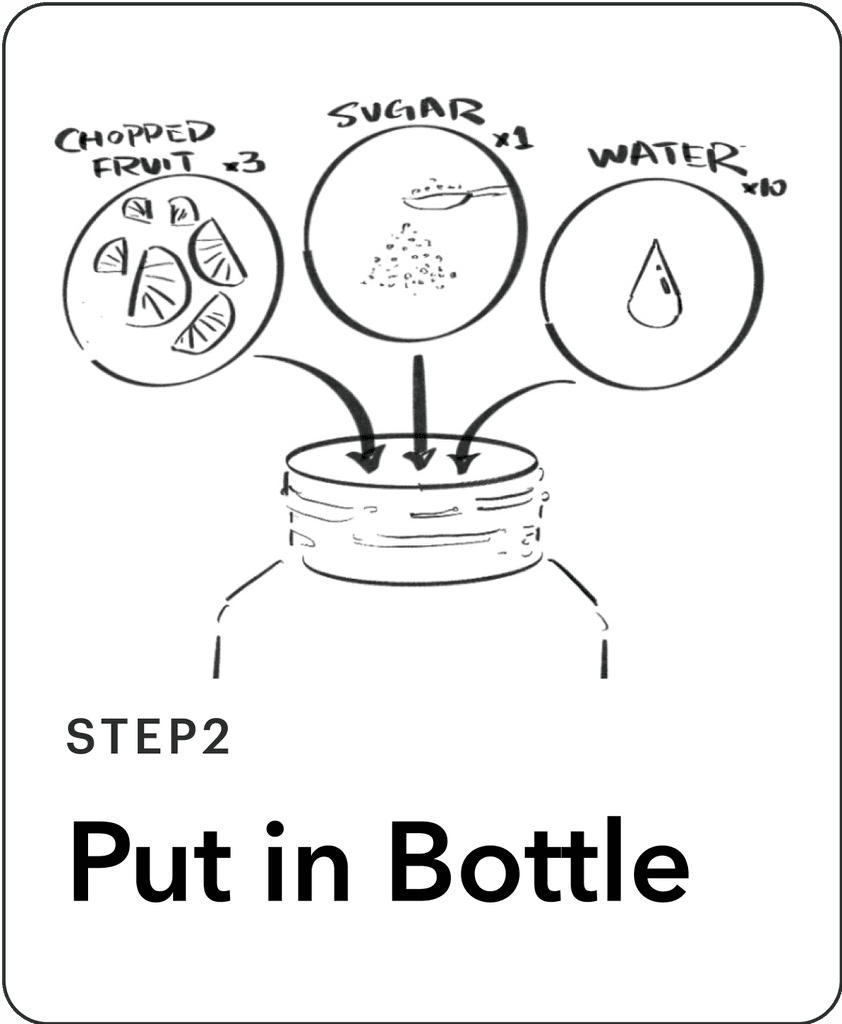

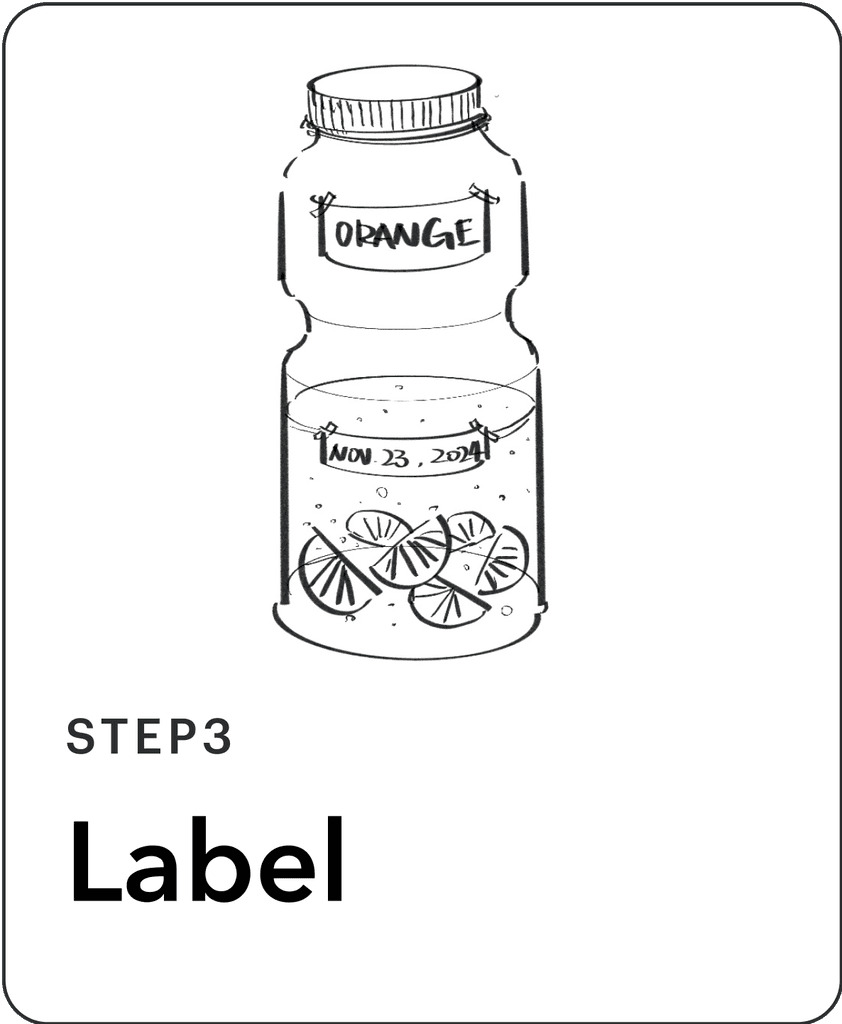

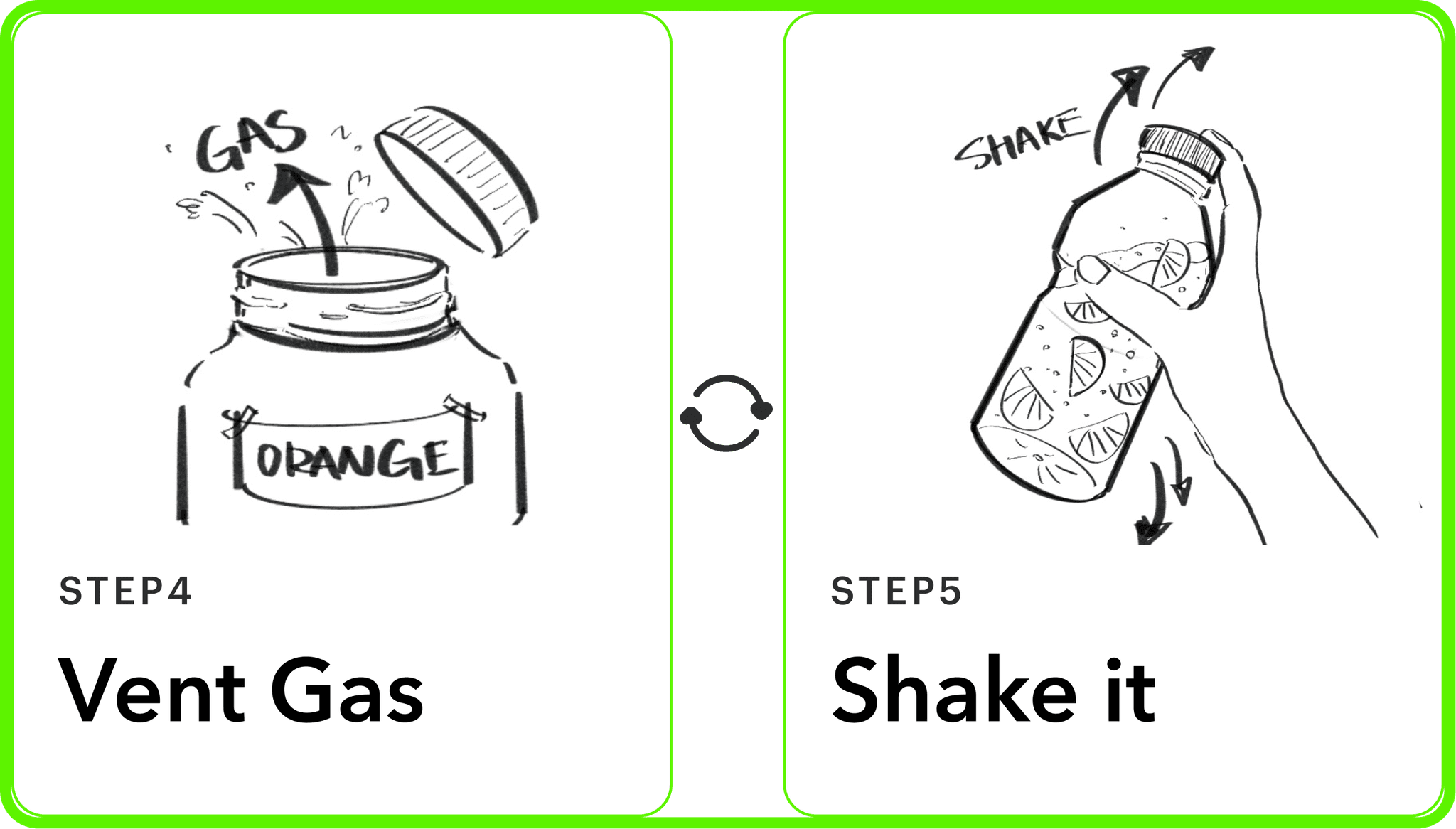

The fermentation process generates a large amount of gas. Traditional methods require users to manually vent gas twice daily for up to 3 months.

Additionally, users lack a reliable way to monitor the process, making it difficult to determine success until the very end.

1st Prototype

DESIGN

To address the issues, we first developed a prototype using a premade airlock and a photoresistor. We connected the top of the container to the airlock with a soft tube, allowing users to check the container's seal through the photoresistor. Inside the box, there is also a temperature/humidity sensor to monitor the environment.

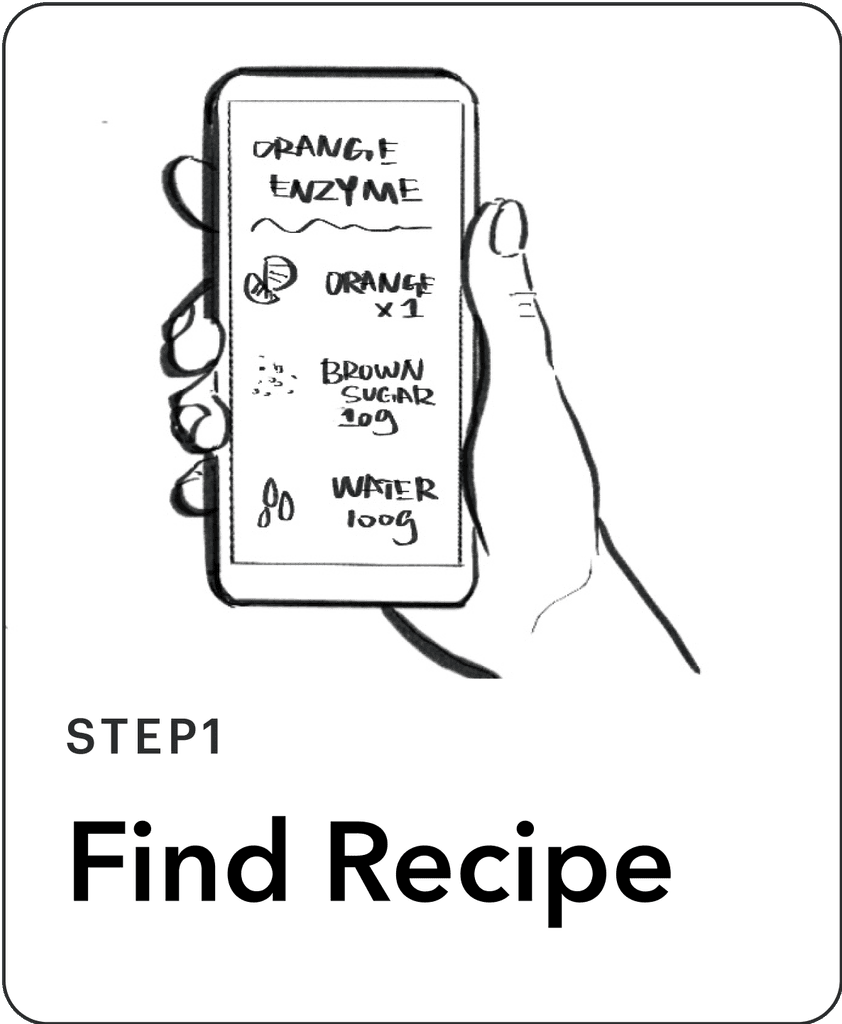

In addition to the physical prototype, we designed a mobile app where users can view recipes, monitor the eco-enzyme status, and access environmental data.

PROBLEM

However, the current design has several problems:

1. The soft tube is too bulky for users to manipulate.

2. The tube connections are hard to seal.

3. The mechanism of using a photoresistor to monitor the dark solution in the airlock is difficult to maintain over a long period.

Final Prototype

As an iteration, we developed our final design to address the problems identified in our previous prototype.

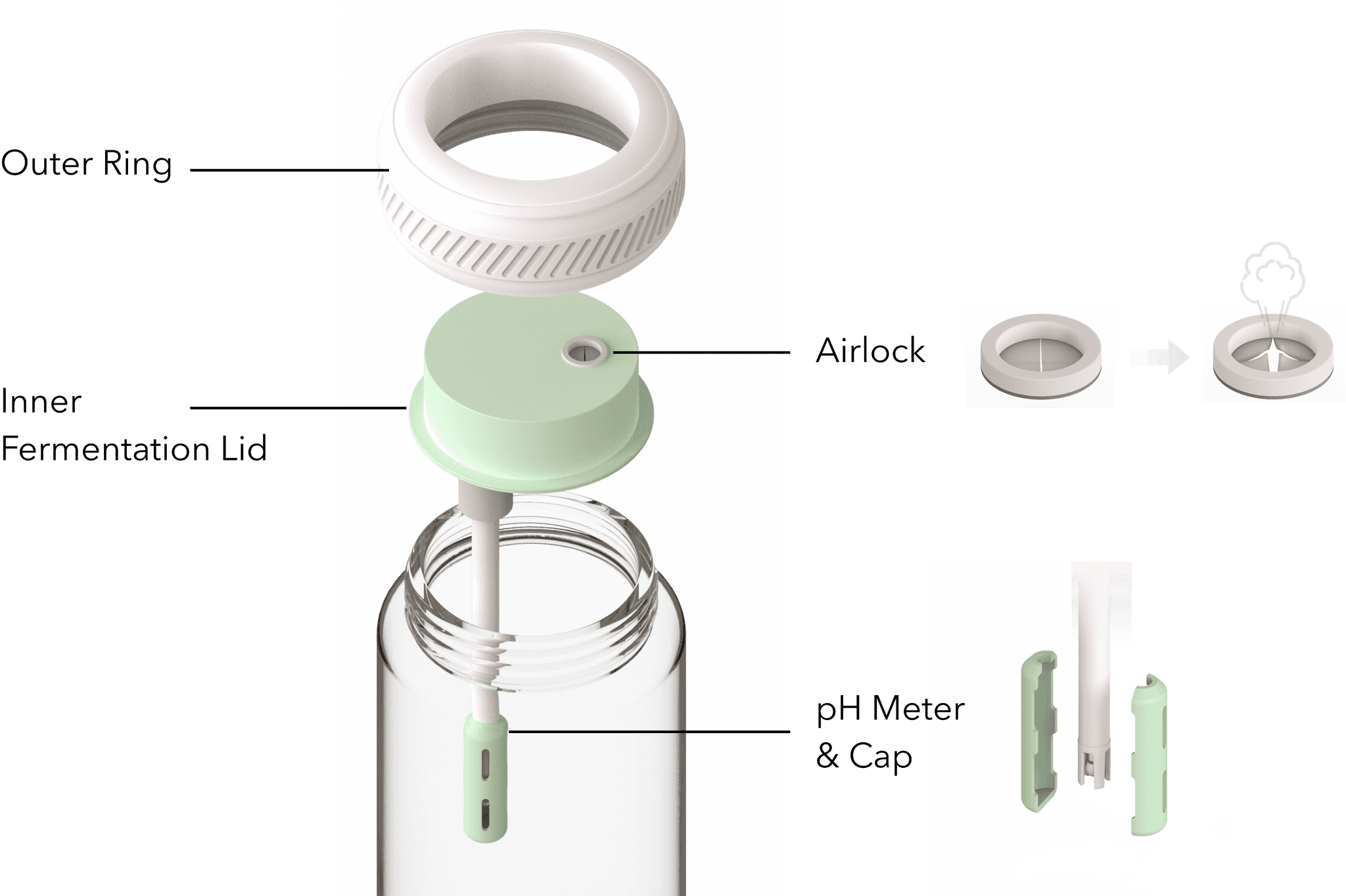

We designed the cap structure with an inner lid and an outer ring to achieve two main objectives: first, to ensure optimal sealing, and second, to allow for easy replacement of the inner cap with different functionalities, such as a filter lid for pouring out the eco-enzyme after the fermentation process is complete.

AIRLOCK + pH METER

The inner fermentation lid has a one-way airlock that allows gases generated during fermentation to escape automatically.

The inner lid also includes a capped pH meter. The pH meter track the pH level of the solution, and accurately reflect the progress of the fermentation, and alert user if the solution is spoiled.

The cap outside the pH meter will avoid our meter from directly touching the fruit inside the jar, which could negativelt affect the pH level readings.

INTERCHANGABLE LID

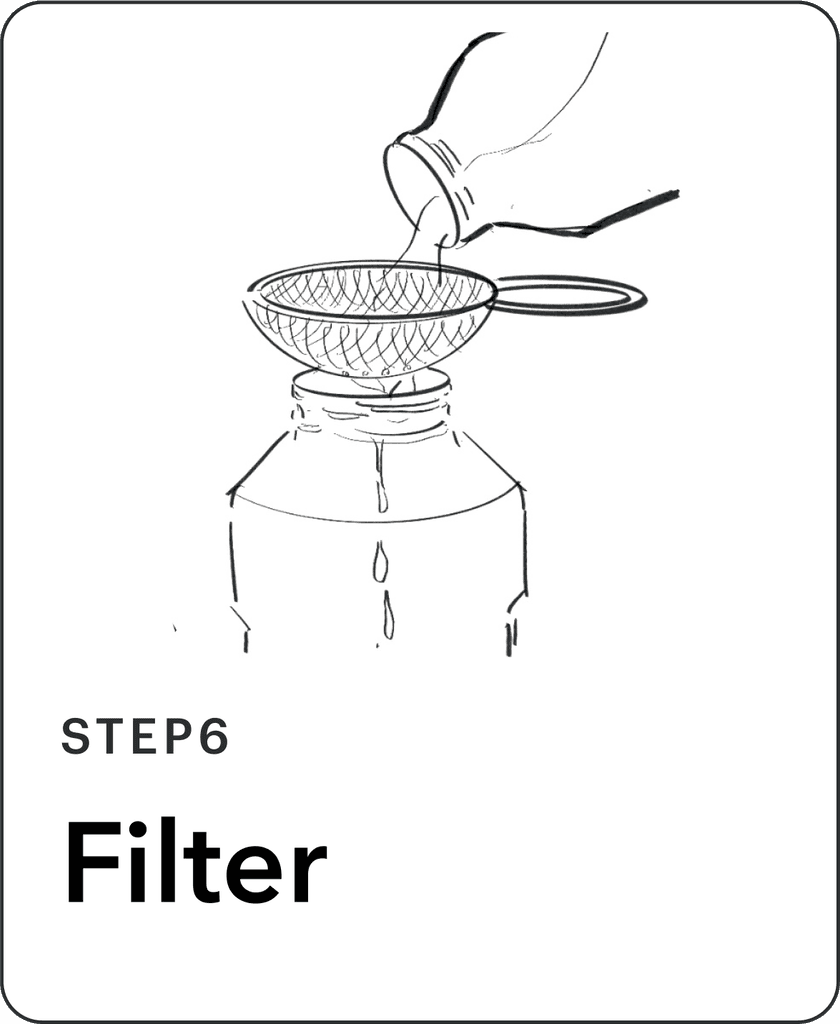

We designed the cap structure with an inner lid and an outer ring to achieve two main objectives: first, to ensure the best sealing, and second, to allow for easy replacement of the inner cap with different functionalities, such as a filter lid for pouring out the eco-enzyme after the fermentation process is finished. We are imagining more variety of inner caps with different function, such as a large open lid, or a spray head, to come with the set.

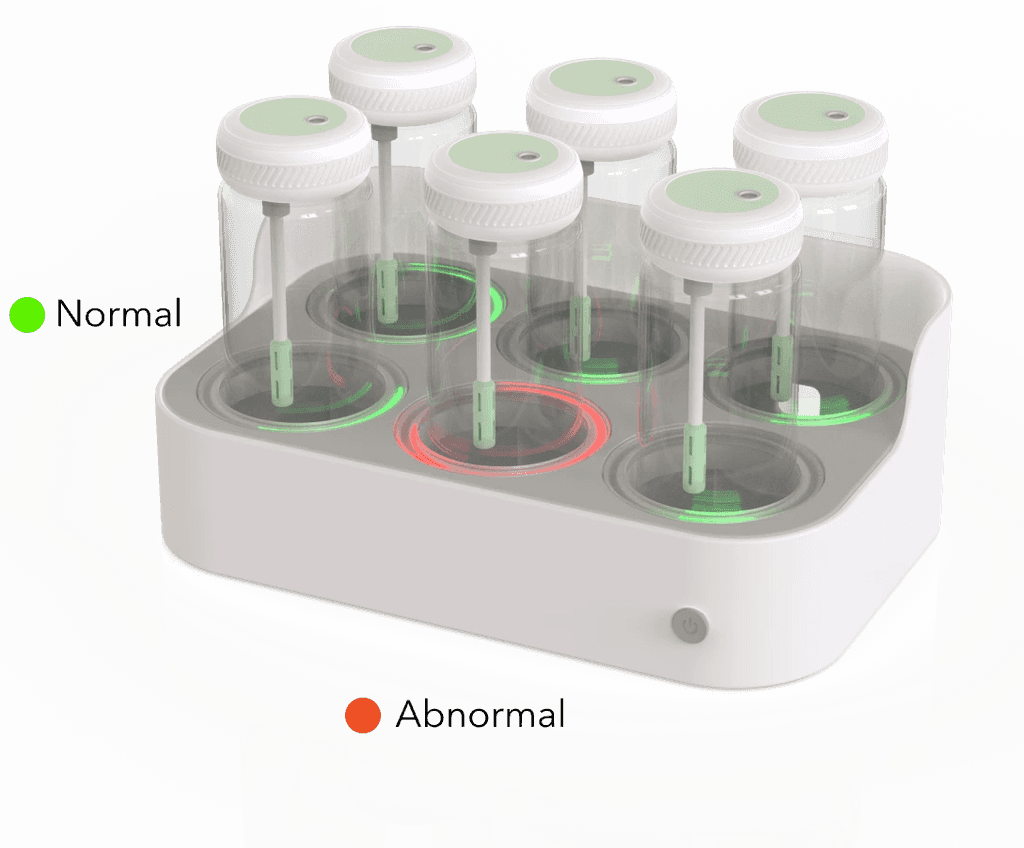

LED INDICATOR

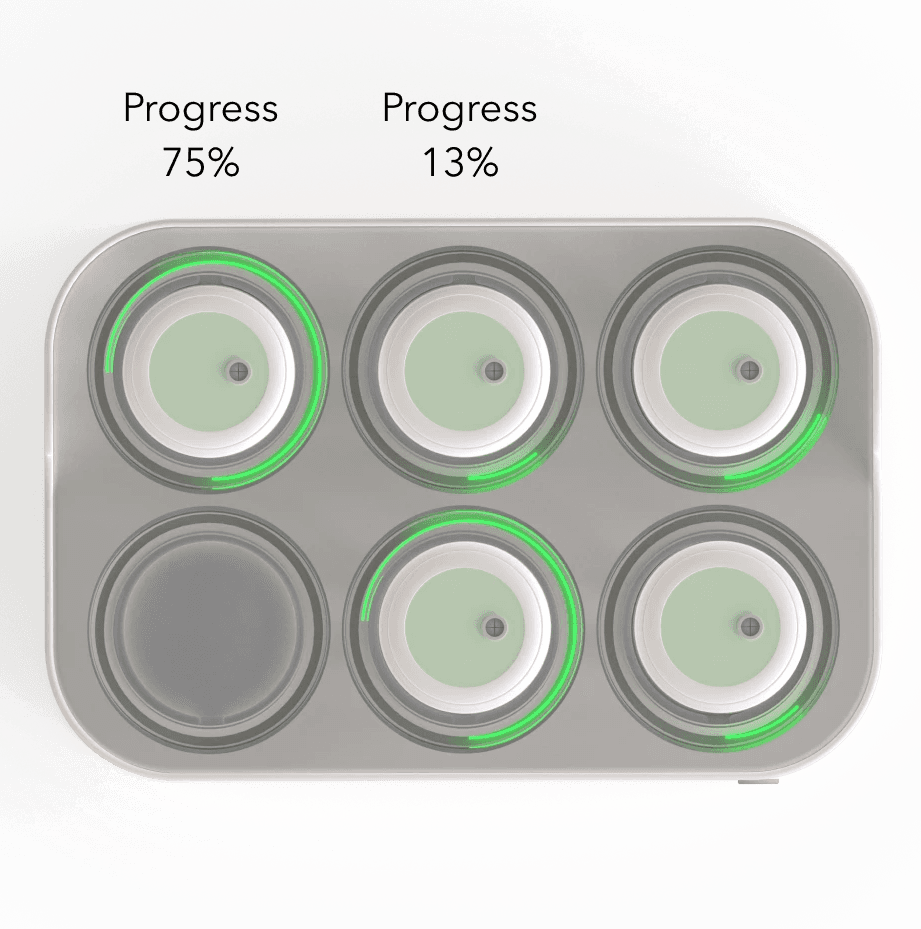

For the incubator, we designed it to use LEDs to indicate the status of the eco-enzymes. Inside the box, there are six force resistors, each corresponding to an LED ring. When a bottle is placed in the incubator, the program retrieves information related to the date, progress, and potential spoilage, and displays the corresponding effect on each LED ring.

The proportion of the ring represents the progress of fermentation. And a green light signifies that the fermentation is in good condition, while a red light indicates that the fermentation might have failed.

Tools